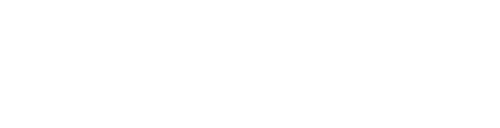

I wanted to measure the impact of the Vertical Tracking Angle (VTA) on sound quality and started by setting up a mini testing lab:

Why did I decide to research VTA?

Reason 1 – very close to my beliefs, although controversial article about the impact of VTA micro adjustments on the sound:

https://www.tnt-audio.com/sorgenti/vta_e.html

Reason 2 – one of the improvements to the latest version of the BennyAudio tonearm which allows for adjusting VTA during playback (because I believe that VTA does matter).

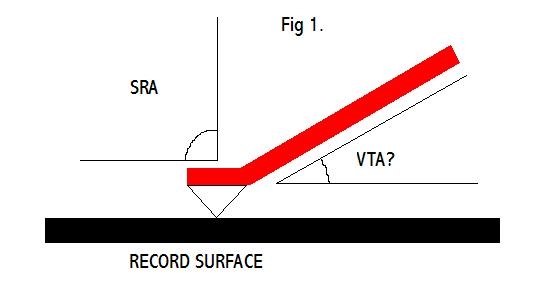

First, a bit of theory. VTA is often confused with the angle the cantilever makes with the record surface.

source: tnt-audio.com

It is, however, more complicated than that. VTA is in fact the angle between the cantilever pivot point and the stylus/groove contact point. Neither is visible.

source: forums.stevehoffman.tv

To make our lives easier, cartridge manufacturers recommend aligning the headshell parallel to the record surface. That is your starting point.

What next?

From my experience, VTA can in some circumstances have a significant impact on cartridge performance. How does it work and what angle should we aim for?

VTA is provided in the spec of each cartridge type alongside other technical details such as dynamic compliance and tracking force. Unfortunately, it is not easy to measure that angle, even if we know the VTA value (see drawing above).

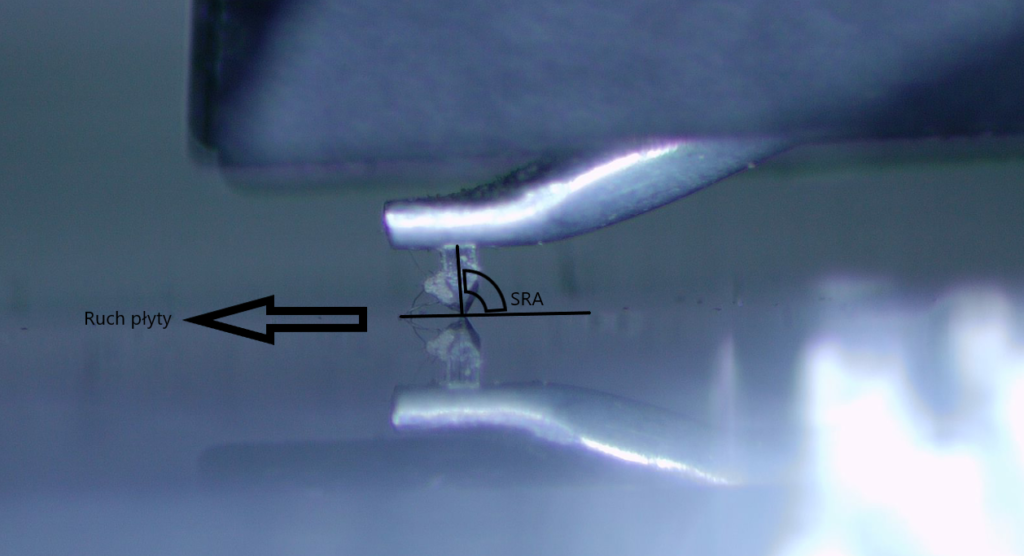

What can we measure then? The common reference point for all cartridges is the Stylus Rake Angle (SRA).

In essence, the rake angle and the cutting stylus angle should be the same.

What is a cutting stylus? This is best explained by briefly outlining the manufacturing process, which starts with a master disc and ends with a vinyl record played on your turntable. Master records are cut on a special machine called a mastering lathe. The cutting stylus is razor sharp, which allows it to etch the recorded sound into the disc.

Master discs are cut at 92-93 degrees SRA. Why? At this angle, a continuous thread of lacquer comes out of the back of the cutting stylus that is a lot easier to remove than the chunks of lacquer you get when cutting at 90 degrees. This video by vinyl guru Peter Ledermann explains it all in graphic detail

(https://www.youtube.com/watch?v=Kt___Ct_zRU).

Why should we also set the SRA of our cartridge stylus to 92-93 degrees?

Because it helps the stylus edges stay parallel to the record groove walls. It will allow the stylus to trace as much groove modulation as possible, especially at high frequencies. How does it work?

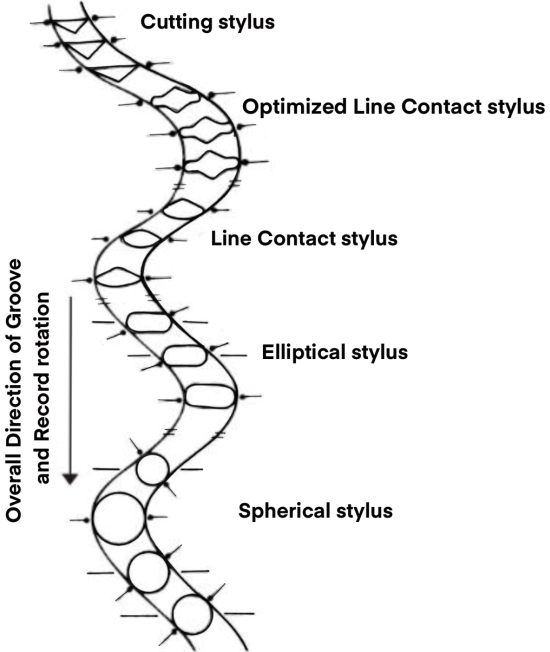

A lot depends on the stylus shape. Essentially, the more complex the shape (that mimics the cutting stylus profile), the more accurate the record tracking. This is why we should be adjusting not only VTA but also azimuth, tracking angle, tracking force, overhang and even anti-skate.

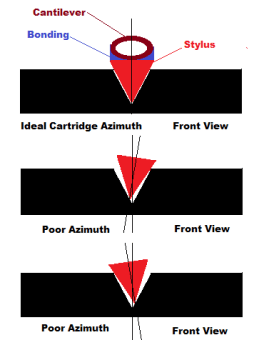

When talking about VTA, it is important to mention azimuth. It refers to the horizontal balance of the cartridge, which in turn determines the angle at which the stylus sits in the record groove:

The table below (‘Front view’ line) shows how various stylus shapes sit in the groove – less complex shapes on the left have a smaller contact surface area. Hence, we could say that stylus adjustment, including VTA, is fairly straightforward, as any minor inaccuracy would not affect the sound quality. A good example of that is DENON DL103/103R- it needs a good quality tonearm but can be adjusted quite easily.

In more complex stylus shapes, the contact surface area is increased, which requires more accurate azimuth adjustment. This makes setting the stylus edge parallel to the record grooves even more important.

Viewed from above, the readings for the elliptical and spherical stylus profiles are off

for both the left and right channels. Yet more proof that these stylus shapes are not audiophile-friendly:

So how do we adjust SRA for more sophisticated stylus profiles?

- By ear – as long as the tonearm has as an on-the-fly VTA adjustment feature (just like Benny).

- Using a microscope.

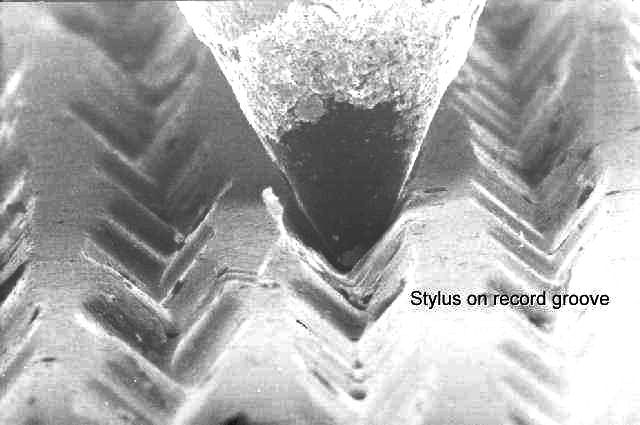

With the more challenging microscope method, you should drop the stylus onto the record so that force is applied to the cantilever, as per the cartridge spec.

Instead of a vinyl record, it is best to use a CD, which has similar thickness and will provide a horizontal mirror image.

What type of device should we use? Definitely not a cheap 1600x digital zoom microscope. I have tried one and would not recommend it. What we really need is a professional digital microscope or a digital camera with at least a 300x lens.

To make things more complicated, we should check if the cantilever flexes during playback, as is the case with Lyra cartridges. If it does, we will have to take a photo when the record is spinning and then measure SRA. Otherwise, we can just measure it in a static position.

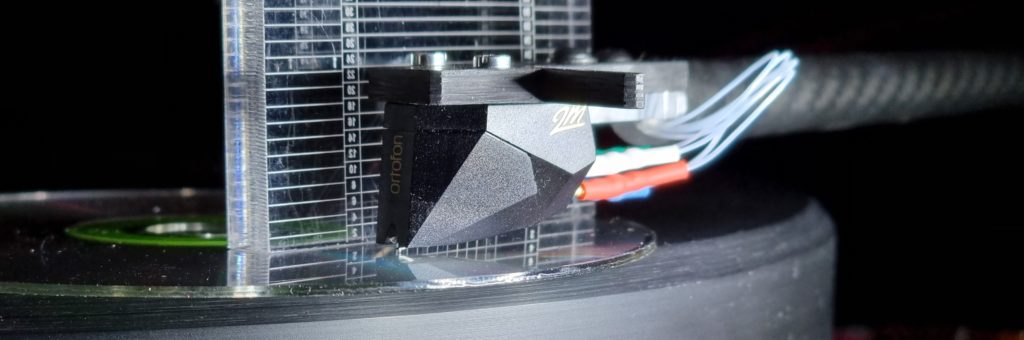

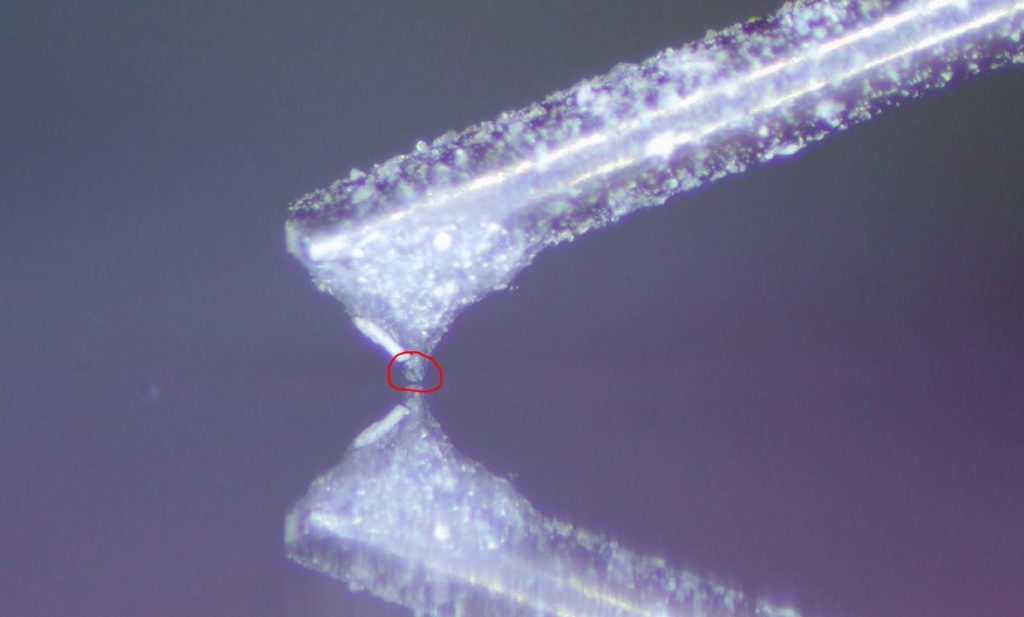

The image above shows the Ortofon 2M Black cartridge with a Shibata stylus, which has a complex profile that requires accurate adjustment. The cantilever stays still during playback, and therefore we can use the static measurement method.

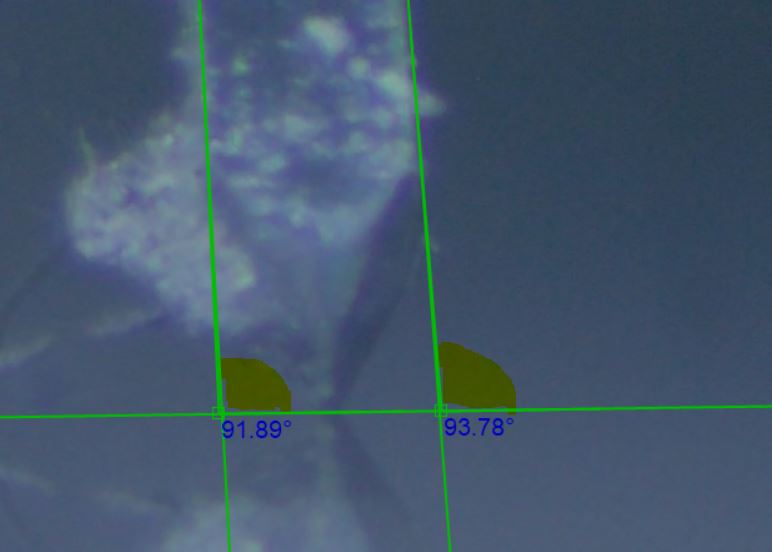

SRA can be measured in a number of different ways, but the trick is to capture the stylus axis and its angle.

With the 2M Black cartridge below, I got the median angle of 92.8 degrees captured from opposite stylus edges – almost perfect (it sounds good too).

Another example – the Lyra Delos cartridge, which has a highly complex Micro Ridge stylus fitted to a boron cantilever.

The stylus is so tiny that SRA must be measured from its back edge and during playback due to the flexing cantilever. According to my observations the Lyra Delos worked best with the headshell aligned exactly parallel to the record surface.

To conclude – VTA is definitely important, but micro-adjustments will not always change the cartridge’s performance.